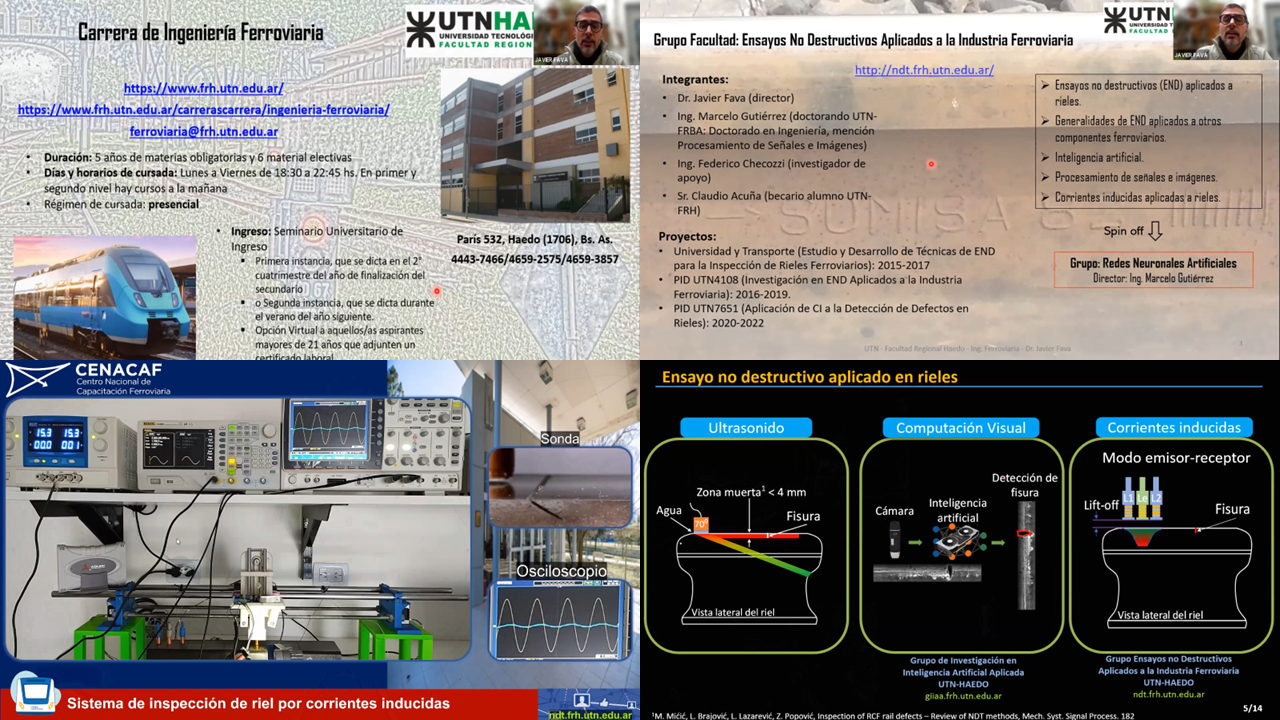

Ensayos No Destructivos Aplicados a la Industria Ferroviaria

Perfilado de sección

-

;

Non-Destructive Testing Applied to the Railway Industry

Universidad Tecnológica Nacional

Facultad Regional HaedoOur main research topics are rail defect detection and evaluation system and railway signal processing.

Description

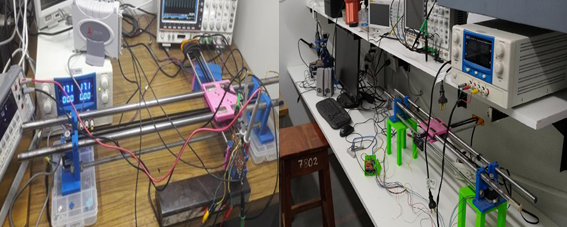

We're working on a rail inspection device that uses Eddy Current Testing (ECT). This device is completely designed and manufactured in the laboratory. It includes a XYZ stage as well as all of the components of an ECT kit. Among the enhancements are the design and manufacture of new probes, the improvement of the electronics for signal sending and receiving, processing of the obtained ECT signals (here the development of a technique to reduce the lift-off signal is highlighted), and the study of the most suitable test conditions.

First prototype device for ECT rail inspection - Lab equipment & instrumentsRecently

- 📢 The Director of the group, Dr. Javier Fava, will participate in the symposium "Present and future of transport safety in Argentina and the region", on April 25, 26 and 27, 2023. Argentine Catholic University – Auditorio Juan Pablo II (Edificio San José)

Alicia Moreau de Justo 1680, CABA, Buenos Aires, Argentina

People

Role Photo Contact About Director

Javier Fava

jfava@frh.utn.edu.arProfessor in Physics at UTN-FRH and PhD in Materials Science Assistant Federico Checozzi

FedericoElectronics Engineer -

Research

PID 7651: "Application of eddy currents to the detection of defects on rail tracks". Date of expirate: 31/12/2022

Research objectives

The general and interrelated problems, which are the safety of railway transport and the reliability of the railway system as a whole (reliability in the sense of carrying out its function in a planned manner), this project attempts to address an aspect of the non-destructive testing on rail tracks. More specifically, within the wide range of NDTs, this research aims to contribute to the application development of eddy current method (and related electromagnetic techniques) to detect defects produced by RCF and evaluate their damage, applying intelligent algorithms that allow an automatic inspection in service. For this, we propose the following objectives:

General objective

✅Contribute to the total quality of the railway system by studying the application of a non-destructive inspection system that allows detecting and evaluating the damage of rail defects caused by the RCF phenomenon.

✅Study the defectology associated with the FCR phenomenon in rails to know the relevant parameters to apply a non-destructive inspection by ECT and related electromagnetic techniques.

✅ Establish the dataset for training the artificial neural network.

✅Develop programming and implementation capabilities in the appropriate programming language for the requirement.

✅Contribute with a modern non-destructive inspection of rail tracks in service through the application of the ECT method, including signal analysis techniques that allow the identification of different types of defects and the evaluation of their damage automatically.

Dr. Javier Fava

DirectorActividades: 0 -

Graduate students

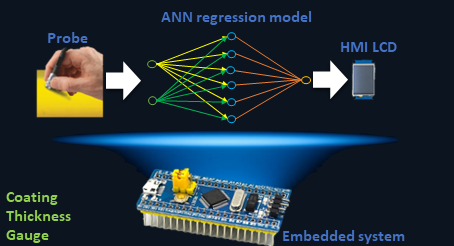

Claudio Acuña Pavese, 2022, “Thickness gauge using the eddy current method”.

Technical summary

Non-destructive testing (NDT) by eddy currents (EC) is a reliable evaluation method that is applied in different areas such as nuclear, the petrochemical industry, air and rail transport, among others. The wide use of coating meters is known, both in different industries and in research and development laboratories. Generally, these devices are manufactured to perform measurements on a limited number of substrates, reducing the range of applications. In this context, the project aims to develop and implement artificial neural network (ANN) algorithms and build a functional prototype for field application in an embedded system. The sensor is composed of a Colpitts oscillator. The impedance of the resonator tank is modified according to the lift-off (in EC lift-off is called the separation between the probe and the component to be inspected), and this generates changes in the resonance frequency. The system calibration curve is determined through the variation of the resonance frequency as a function of the lift-off. Eddy currents method, like all NDT methods, is a comparative method that needs a calibration curve in order to be implemented. The sinusoidal signal coming from the probe enters the embedded system that will be in charge of conditioning it. In the next stage of the device, a calibration must be performed depending on the substrate being used. Calibration is performed by training an ANN, which will have the output frequency of the oscillator as data set according to the thickness of standard gauges. In the last stage, the trained ANN will return the value of the coating thickness and this parameter will be displayed on an HMI interface or screen. The system will be powered by a rechargeable battery and recharging will be through an external power supply. The portable device must work with thicknesses between 25 and 905 microns on 6061 aluminum and Zry-4. Consequently, this project will contribute to the research and development group "Non-destructive testing applied to the railway industry" of the Haedo Regional Faculty and to the industry that uses this measurement technique.

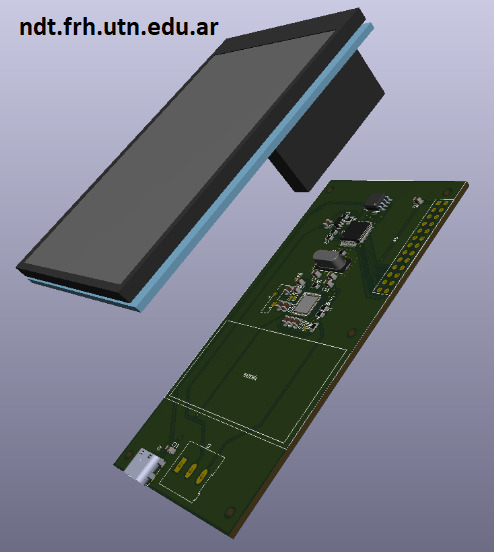

Graphical abstract

Progess

First prototype.

Finalizing the main control board with the LCD.

As part of my graduation project, I was able to interface a 3.5" RPi Display with an STM32 Blue Pill. The objective is to make a coating thickness gauge on Zry-4 tubes used in the nuclear industry. Therefore, the next step is to integrate the probe into the portable device. pic.twitter.com/usTOLQgXMv

— Claudio Acuña (@acuna_cap) October 13, 2022Actividades: 0 -

Development

Please take a deeper dive into our specific contributions by clicking on the links below:

Actividades: 0 -

3D scanner

Auto-leveling is mostly used for exploring surfaces in depth with high precision. Scanning a surface reveals a grid of points representing the surface. When we repeat the same reading, the error is usually less than 0.025 mm.

3D scanner for Eddy Current Testing

Actividades: 0 -

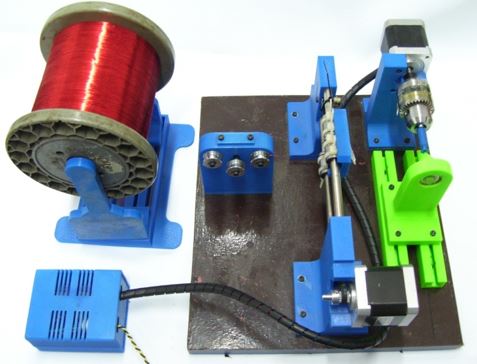

Coil winder

Design and construction of a coil winder. The coil winder is used for the construction of the designed coils.

Actividades: 0

Actividades: 0 -

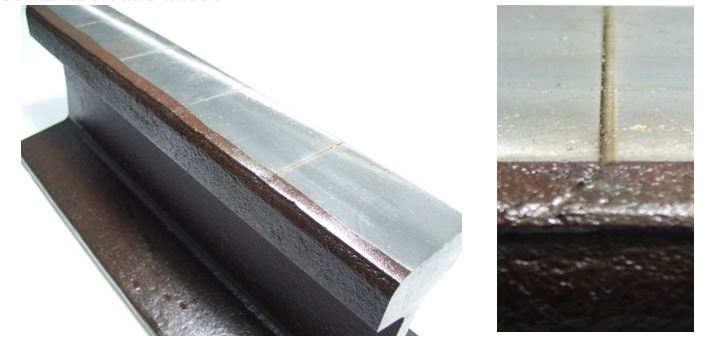

Calibration blocks

Design and construction of ECT test slot patterns. Patterns were built on plates of ferromagnetic material and on pieces of rails.

Skew block

Head-Check block

Actividades: 0 -

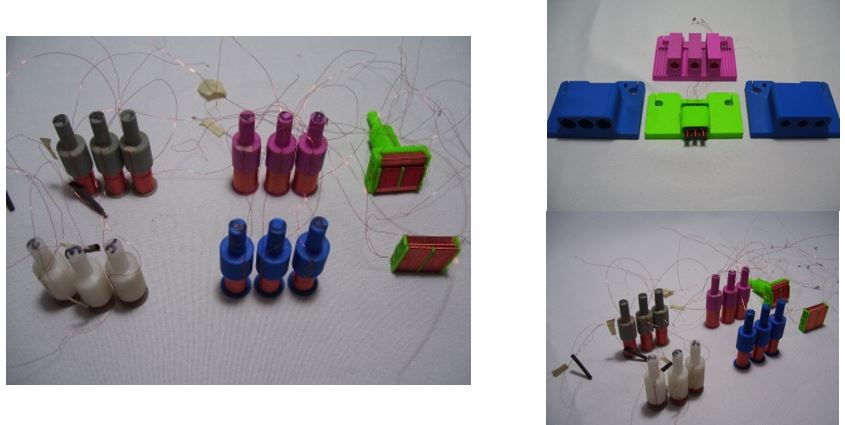

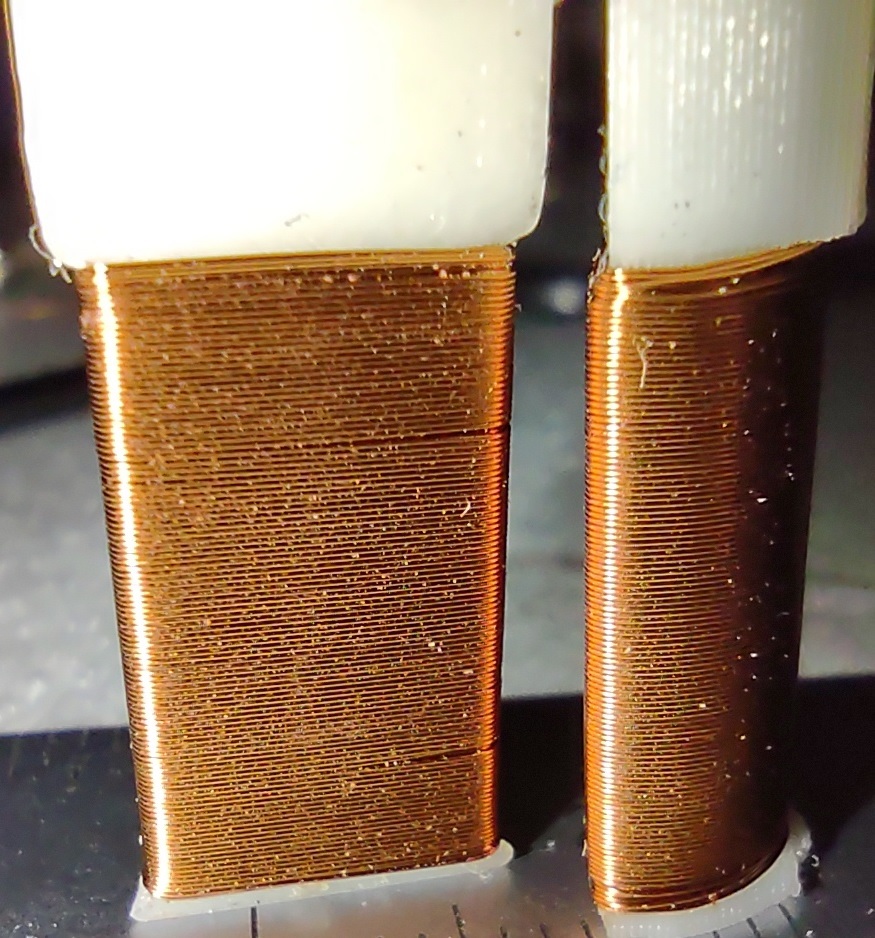

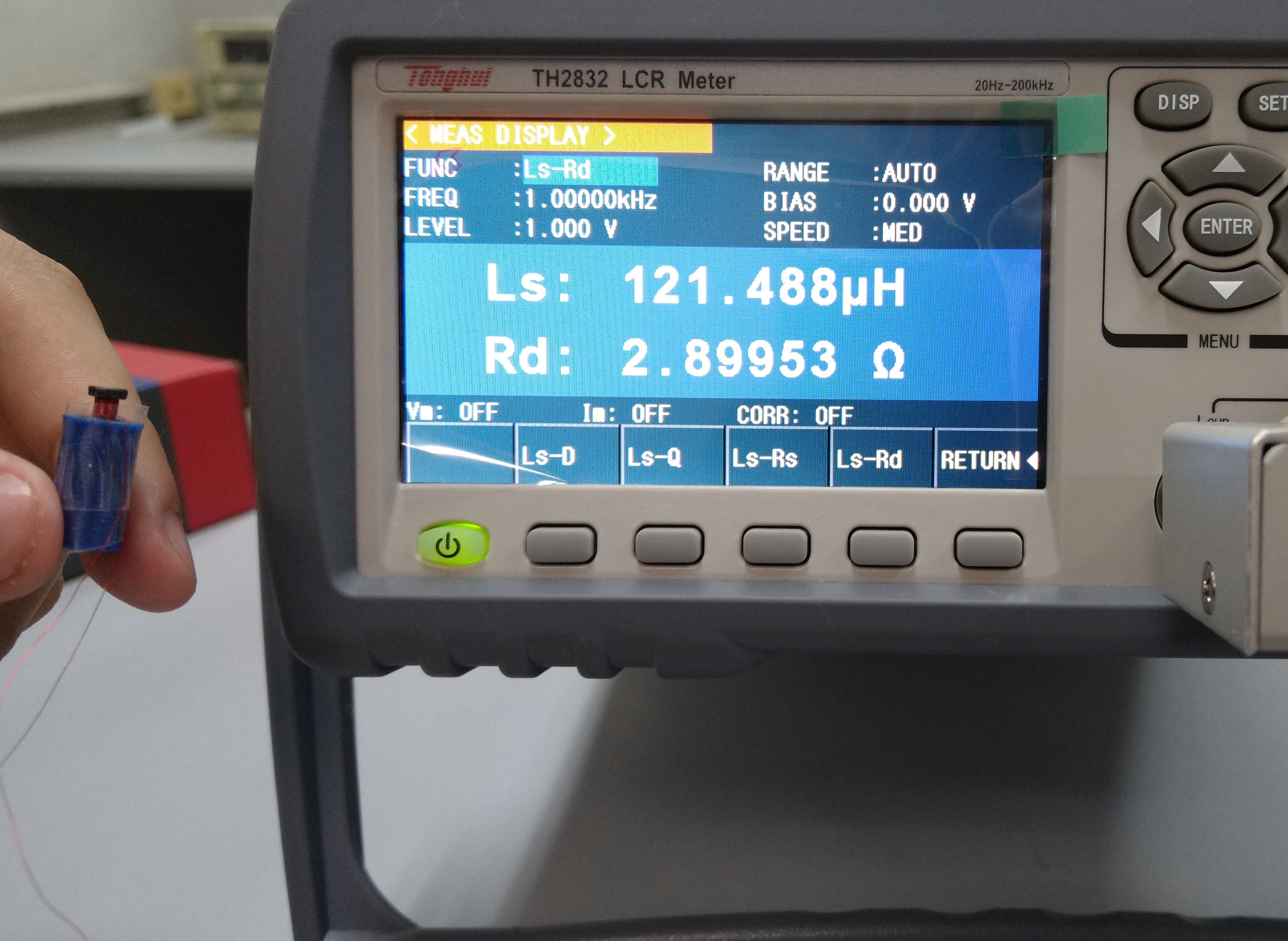

Eddy Current Probes

The research group designed several eddy current probes.

Eddy current coils were designed, constructed, and characterized.

Split-D coil

Characterization of coil properties using a LCR meter

Actividades: 0

Actividades: 0 -

THICKNESS MEASUREMENT

Eddy current techniques are used to measure the thickness of nonconductive coatings on metal substrates in a non-destructive manner. An alternating magnetic field is created at the surface of the instrument's probe using a coil that conducts a high-frequency alternating current (over 8 MHz). When the coating thickness probe is brought close to a conductive surface, the alternating magnetic field creates eddy currents. The size of the eddy currents is affected by the substrate properties and the distance of the probe from the substrate (the coating thickness).

Probe

Set of thickness gauges

Basic stages of the probe manufacturing process

Actividades: 0 -

Conference proceeding

All published papers in reverse chronological order. Downloadable in PDF

Permeabilidad magnética relativa como un párametro efectivo en ensayos por corrientes inducidas sobre aceros ferromagnéticos

Javier Fava ,Fernando Carabedo, Marcelo Gutiérrez

,Fernando Carabedo, Marcelo Gutiérrez . 107° Reunión de la Asociación Física Argentina (2022)

. 107° Reunión de la Asociación Física Argentina (2022)Estudio de la degradación de tubos refrigerantes de Zry-4 de atucha I en solución 0.3M LIOH a 343°C

Liz, Cruz, Javier Fava , León Mosquera. 107° Reunión de la Asociación Física Argentina (2022)

, León Mosquera. 107° Reunión de la Asociación Física Argentina (2022)Inspección de daño tipo head check en rieles ferroviarios

Marcelo Gutiérrez , Javier Fava

, Javier Fava , Juan Vorobioff

, Juan Vorobioff , Tomás Di Fiore. 3er Congreso sobre medios de transporte y sus tecnologías asociadas (2021)

, Tomás Di Fiore. 3er Congreso sobre medios de transporte y sus tecnologías asociadas (2021) Avances en la detección de defectos de fatiga de contacto por rodadura en rieles ferroviarios

Marcelo Gutiérrez , Javier Fava

, Javier Fava , Juan Vorobioff

, Juan Vorobioff , Tomás Di Fiore, Marta. Ruch

, Tomás Di Fiore, Marta. Ruch , Rodrigo Romero. 12er Congreso Regional de Ensayaos No Destructivos y Estructurales (CORENDE XII).Buenos Aires, Argentina; 6 al 8 de noviembre, 2019. Presentado en forma Oral en el XII Corende, el día 08/11/2019.

, Rodrigo Romero. 12er Congreso Regional de Ensayaos No Destructivos y Estructurales (CORENDE XII).Buenos Aires, Argentina; 6 al 8 de noviembre, 2019. Presentado en forma Oral en el XII Corende, el día 08/11/2019.Evaluación de fisuras superficiales en rieles y componentes planos ferromagnéticos por corrientes inducidas

Marcelo Gutiérrez , Javier Fava

, Javier Fava , Tomas Di Fiore, Juan Vorobioff

, Tomas Di Fiore, Juan Vorobioff ;I Congreso Argentino de Ingeniería Ferroviaria; San Miguel de Tucumán, Tucumán, Argentina; 10 al 12 de octubre, 2018. Presentado en forma Oral en el Congreso Argentino de Ingeniería Ferroviaria, el día 13/10/2018.

;I Congreso Argentino de Ingeniería Ferroviaria; San Miguel de Tucumán, Tucumán, Argentina; 10 al 12 de octubre, 2018. Presentado en forma Oral en el Congreso Argentino de Ingeniería Ferroviaria, el día 13/10/2018.Reconocimiento de defectos en rieles ferroviarios por corrientes inducidas aplicando redes neuronales

Marcelo Gutiérrez , Juan Vorobioff

, Juan Vorobioff , Javier Fava

, Javier Fava , Tomas Di Fiore; IX Congreso de Microelectrónica Aplicada; San Fernando del Valle de Catamarca, Catamarca, Argentina; 9 al 10 de octubre, 2018. Presentado en forma Oral en el IX Congreso de Microelectrónica Aplicada, el día 09/10/2018.

, Tomas Di Fiore; IX Congreso de Microelectrónica Aplicada; San Fernando del Valle de Catamarca, Catamarca, Argentina; 9 al 10 de octubre, 2018. Presentado en forma Oral en el IX Congreso de Microelectrónica Aplicada, el día 09/10/2018.Inspección por Corrientes Inducidas de Defectos Superficiales en Rieles Ferroviarios

Marcelo Gutiérrez , Javier Fava

, Javier Fava , Tomas Di Fiore, Juan Vorobioff

, Tomas Di Fiore, Juan Vorobioff ; 1er Congreso sobre medios de transporte y sus tecnologías asociadas; Haedo, Buenos Aires, Argentina; 26 al 28 de octubre, 2018. Presentado en forma Oral en el 1er Congreso sobre Medio de Transporte y sus Tecnologías Asociadas, el día 26/09/2018.

; 1er Congreso sobre medios de transporte y sus tecnologías asociadas; Haedo, Buenos Aires, Argentina; 26 al 28 de octubre, 2018. Presentado en forma Oral en el 1er Congreso sobre Medio de Transporte y sus Tecnologías Asociadas, el día 26/09/2018.Development of a differential test device for eddy current rail inspection

Marcelo Gutiérrez , Javier Fava

, Javier Fava , Tomas Di Fiore, Marta Ruch

, Tomas Di Fiore, Marta Ruch , Rodrigo Romero and Juan Vorobioff

, Rodrigo Romero and Juan Vorobioff ;12th European Conference on Non-Destructive Testing (12th ECNDT); Gothenburg, Sweden; June 11–15, 2018.

;12th European Conference on Non-Destructive Testing (12th ECNDT); Gothenburg, Sweden; June 11–15, 2018.Modelling eddy currents on a ferromagnetic plate: field in the conductor and magnetic permeability as a function of the frecuency

Javier Fava , Fernando Carabedo,Marta Ruch

, Fernando Carabedo,Marta Ruch ,Marcelo Gutiérrez

,Marcelo Gutiérrez ; 12th European Conference on Non-Destructive Testing (12th ECNDT); Gothenburg, Sweden; June 11 – 15, 2018.

; 12th European Conference on Non-Destructive Testing (12th ECNDT); Gothenburg, Sweden; June 11 – 15, 2018.Inspección de rieles por corrientes inducidas: desarrollo de un dispositivo diferencial

Marcelo Gutiérrez , Javier Fava

, Javier Fava , Tomas Di Fiore, Marta Ruch

, Tomas Di Fiore, Marta Ruch , Rodrigo Romero, Adrian Bonomi, Juan Vorobioff

, Rodrigo Romero, Adrian Bonomi, Juan Vorobioff ; 11er Congreso Regional de Ensayaos No Destructivos y Estructurales (CORENDE XI);Neuquén, Argentina; 4 al 6 de octubre, 2017. Presentado en forma Oral en el XI Corende, el día 21/07/2017Actividades: 0

; 11er Congreso Regional de Ensayaos No Destructivos y Estructurales (CORENDE XI);Neuquén, Argentina; 4 al 6 de octubre, 2017. Presentado en forma Oral en el XI Corende, el día 21/07/2017Actividades: 0 -

The beginning

This is our early report on non-destructive testing applied to railway inspection.

Actividades: 2 -

Teaching

Contributions of the R&D group towards the educational community. Currently the documents are used as teaching material in different subjects

Defectos en rieles y elementos para su inspección no destructiva (2022)

Defectos en rieles y elementos para su inspección no destructiva (2022)

Optical methods for rail inspection

Optical methods for rail inspection

Rolling contact fatigue cracking in rails

Rolling contact fatigue cracking in rails

Defectology and test methods non destructive testing applied to wheels and axlesActividades: 4

Defectology and test methods non destructive testing applied to wheels and axlesActividades: 4 -

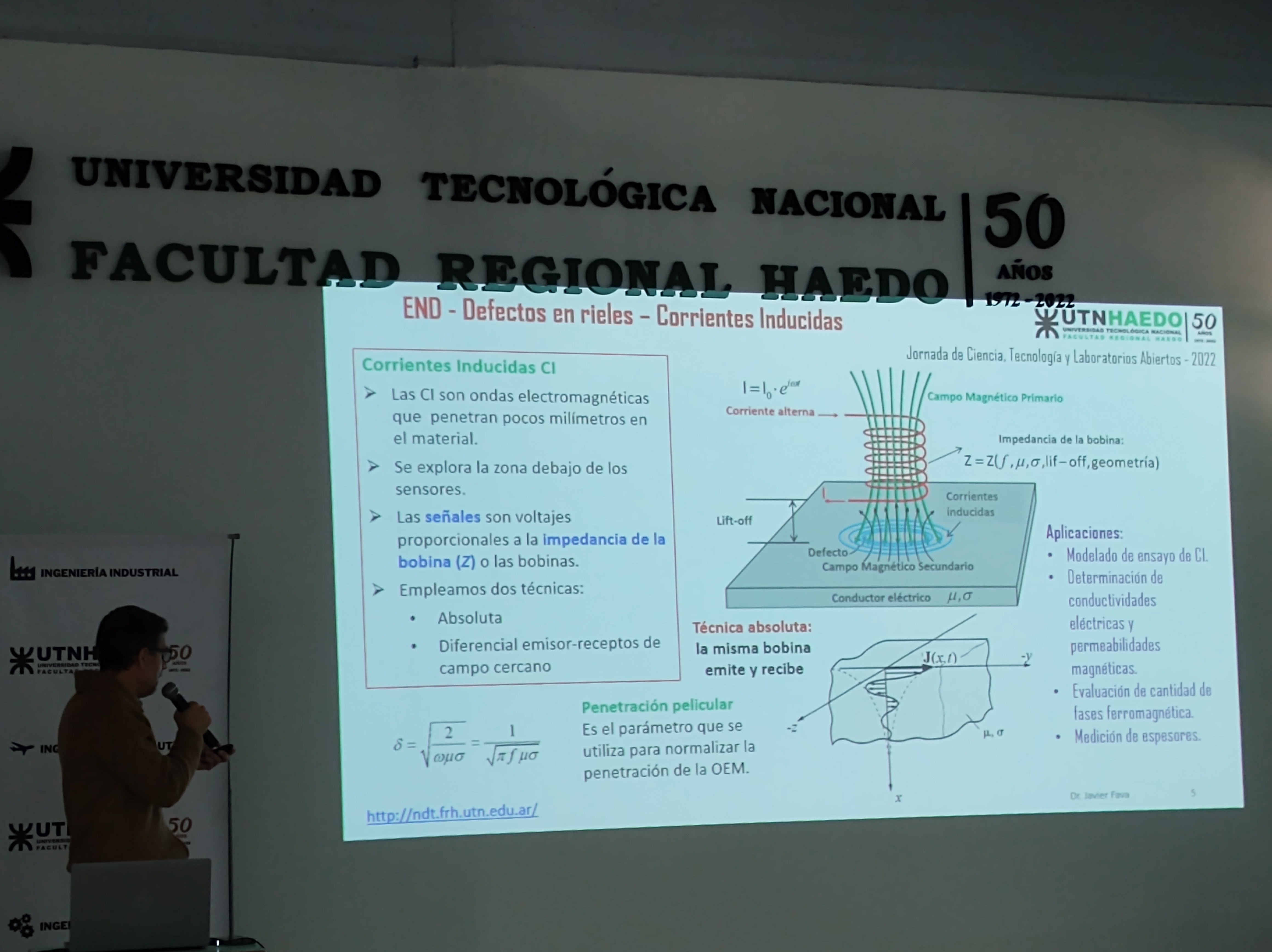

Photos Gallery

Conference on Science, Technology and Open Laboratories(2022)

Our research team has released the results of non-destructive tests applied to the railway industry.

107° Reunión de la Asociación Física Argentina(2022)

This event is the main forum for discussion of Physics in Argentina, bringing together, on average, about 800 attendees each year: among researchers, doctoral students and undergraduate students.

Centro Nacional de Capacitación Ferroviaria (CENACAF)(2022)

The National Railway Training Center offers seminars and training courses for all those who work in the railway sector.

III congreso sobre medios de transporte y sus tecnologías asociadas (2021)

The Third Congress on Transportation medium and its Applied Technologies aims to create a space for deepening knowledge about new technologies related to automotive, land (people and cargo), rail, air, sea and space transport. In turn, the meeting aims to contribute to the improvement of energy efficiency, and to generate greater awareness for the reduction of environmental pollution, promoting an impact on political, economic, social and technological development in Argentina.

XII Congreso Regional De Ensayos No Destructivos y Estructurales-CORENDE 2019

CORENDE proposes a forum to promote knowledge exchange and deepen the discussion of ideas, providing an opportunity for interaction between academic institutions and the industrial environment, promoting the development and coordination of joint activities and projects, and taking advantage of the opportunity to survey the state of NDT teaching and its needs.

I Congreso Argentino de Ingeniería Ferroviaria-I CAIFE 2018

The congress was held on October 10, 11 and 12, 2018, in the city of San Miguel de Tucumán, organized by the Department of Mechanics of the Faculty of Exact Sciences and Technology of the National University of Tucumán.

IX Congreso de Microelectrónica Aplicada (UEA2018)

The IX Congress of Applied Microelectronics (UEA2018) was held on October 9 and 10, 2018, under the scope of the University Network of Electronic Engineering of the Argentine Republic. The event was organizaded by the Electronic Department of the Faculty of Technology and Applied Sciences of the National University of Catamarca.

XI Congreso Regional de Ensayos No Destructivos y Estructurales-CORENDE 2017

CORENDE proposes a forum to promote knowledge exchange and deepen the discussion of ideas, providing an opportunity for interaction between academic institutions and the industrial environment, promoting the development and coordination of joint activities and projects, and taking advantage of the opportunity to survey the state of NDT teaching and its needs.

Actividades: 0 -

PDF papers

Downloadable in PDF

Actividades: 8 -

Proyecto:“Estudio y Desarrollo de Técnicas de Ensayos No Destructivos para la Inspección de Rieles Ferroviarios”, Nro. 32-64-054 del Programa Universidad y Transporte Línea Aplicada, convocatoria 2014 de la Secretaría de Políticas Universitarias. The project was approved at the end of 2015, and the final report was submitted at the end of May 2017.

Vigencia: 28/08/2015 a 31/05/2016

Actividades: 0 -

Location

NON-DESTRUCTIVE TESTING APPLIED TO THE RAILWAY INDUSTRY

National Technological University

Haedo Regional Faculty

532 Paris Street

Buenos Aires, Argentina

Phone: +54-011-4443-7466

Fax: +54-011-4443-0499

Website: ndt.frh.utn.edu.arActividades: 0